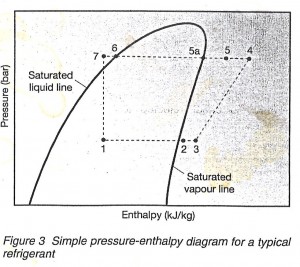

The operation of a simple system is shown in Figure 3 which shows the pressure-enthalpy chart for a typical refrigerant. The enthalpy (energy content) of the refrigerant varies with its pressure, temperature and state. The curve is the saturation curve.

- On the left part of the curve, the refrigerant is just a pure (saturated) liquid.

- On the right part, it is a pure (saturated) vapour.

- Inside the curve the refrigerant is a saturated mixture of liquid and vapour.

- In the area to the left of the curve the refrigerant is a sub-cooled liquid (i.e. a liquid below its saturation temperature).

- In the area to the right of the curve is a superheated vapour i.e. at a temperature above its saturation temperature.

1→2 Low pressure liquid refrigerant (1) in the evaporator absorbs heat energy from its surroundings usually air, water or some other process liquid, which fuels its change of state from a saturated liquid to a saturated vapour. In certain systems, at the evaporator exit (2) the refrigerant vapour is slightly superheated as shown.

2→3 the slightly superheated refrigerant vapour picks up more heat energy from ambient air around the pipe work between the evaporator and the compressor. This is bad efficiency.

3→4 The superheated vapour enters the compressor where its pressure is raised. There will also be a large increase in temperature, because some of the energy of compression is transferred into the refrigerant (superheat).

4→5 The very hot vapour loses a small amount of heat to ambient air in the pipe work between the compressor and condenser. This is good for efficiency.

5→6 The high pressure superheated vapour flows into the condenser. The initial part of the cooling process (5-5a) de-superheats the vapour before it then turns back into saturated liquid (5a-6). The cooling for this process is usually achieved by using anbient air or water.

6 →7 A further reduction in temperature may occur between the condenser and the expansion device so that the refrigerant liquid is sub-cooled as it enters the expansion device. This is good for efficiency.

7 →1 The high pressure sub-cooled liquid passes through the expansion device which reduces its pressure and results in the temperature of the refrigerant going down. There is however no energy loss or gain through the expansion device.

The outlet of the expansion device/inlet to the evaporator does not lie on the saturated liquid line. This is because at the lower temperature the refrigerant cannot contain as much heat. This excess heat causes some of the refrigerant to evaporate (flash off) in expanding.

How a refrigeration system works the hardware

- Refrigeration system the hardware

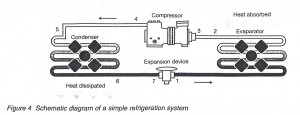

The operation of the main system components is shown in Figure 4 and described below. All systems must contain these components.

1→2Refrigerant absorbs a lot of heat in the evaporator.

The evaporator contains refrigerant boiling at low pressure. As the refrigerant boils or evaporates it absorbs a lot of heat. This heat is removed from whatever surrounds the evaporator, usually air this is then circulated around the food

- The cooling effect of the evaporator is governed by the difference in temperature between the medium being cooled and the evaporating refrigerant. The wider the temperature difference the greater the rate of heat transfer also the size and design of the evaporator.

- Different types of evaporators are used for air cooling and for cooling a liquid.

2→3 Refrigerant vapour absorbs a little more heat in the suction line.

- The refrigerant absorbs heat from the ambient temperature air around the suction line between the evaporator and the compressor this superheating is minimised by insulation to maintain efficiency.

3→4 Refrigerant vapour is compressed in the compressor

The compressor is an essential component in a refrigeration system it compresses refrigerant vapour from the low pressure of the evaporator to the higher pressure of the condenser it is the heart of the system because it is the component which causes the refrigerant to flow around the system which results in saturation temperature. The compressor adds energy and maintains the operation of the process.

Compressors are driven by an electric motor and are the main power users in refrigeration systems and are assembled in three forms: 1 Open type- piston. 2 Semi Hermetic- Rotary-Screw. 3 Hermetic Scroll.

4→5 Refrigerant vapour loses some heat in the discharge line.

The high pressure refrigerant vapour flows from the compressor to the condenser losing a small amount of heat energy to ambient air which should be maximised for best efficiency.

5→6 Refrigerant loses a lot of heat in the condenser.

The condenser contains the refrigerant which is changing from a superheated vapour into a liquid at high pressure. A lot of heat energy is released during this process which is either rejected to ambient air or to cooling water. The condenser capacity is affected by the temperature of the cooling air or water or by the size and design of the condenser.

6→7 Liquid refrigerant subcools in the liquid line.

The liquid refrigerant flowing between the condenser and expansion device usually loses heat to ambient air. This sub cooling is beneficial to the performance of the system since it increases refrigeration capacity without increasing the power input.

7→1 Refrigerant pressure is dropped in the expansion device.

An expansion device maintains the pressure drop between the condenser and evaporator. The refrigerant saturation temperature also reduces as the pressure drops. The expansion device is sized to pass the required amount of refrigerant at the minimum likely pressure drop across the system.