Domestic frost free appliances became popular in the UK in the early 1990’s. The principle of self defrosting freezers is very simple, instead of manually defrosting the evaporator every 4-6 months the frost free appliance defrosts itself each day.

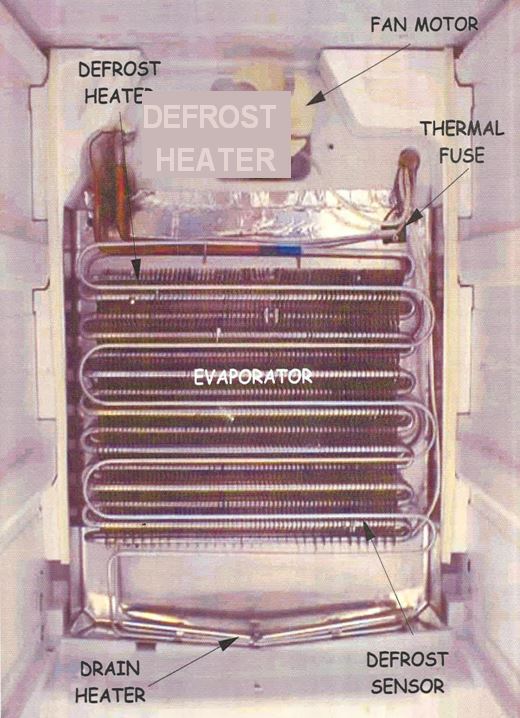

This is acheived by installing a heater, controlled by a defrost timer, onto the evaporator. The defrost timer must leave the heater on long enough to defrost any ice that has built up on the evaporator but not long enough for the food inside the cabinet to defrost.

Electronic Defrost Timer (PCB) – Samsung-Leibherr-Whirlpool-LG-Bosch-Maytag

Most electronic timers have a self test mode which can be accessed by referring to the service information handout/Bulletins.

If an appliance which is fitted with an electronic timer is disconnected from the mains supply, when the power is reconnected the timer will check the temperature of the evaporator and determine if a defrost is required (usually colder than -5°C)

Some frost free models that have an electronic display will show a fault code, this will help to identify the problem area. The fault code will be explained in the service information.

Types Of Frost Free Refrigerator Section

Air blown (Parasitel) – Whirlpool-Maytag-LG-General Electrics/GE

This type of refrigerator section relies on cold air blown from the freezer section to chill the fridge compartment. The air flow is usually controlled by a sliding vent or baffle operated by a thermostat.

Please note if replacing the thermostat on an air blown appliance that an air thermostat must be fitted (air thermostats sense air temperature and not the evaporator temperature).

Wet wall – Miele-Liebherr-Bosch

This type of refrigerator section works in the same manner as a standard larder refrigerator (ice will form on the rear wall of the liner and then defrost on the off cycle

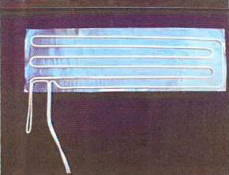

The drain heater is located in the drain channel of the freezer section. It ensures that no ice forms in the drain channel or blocks the drain hole during the defrost period.

brain heaters are usually held in position using adhesive aluminium tape.

Thermal Fuse – Samsung-Whirlpool-Maytag

The thermal fuse protects the interior of the cabinet against heat damage from the defrost heater.

Thermal fuses rupture between +72°C and +84°C. Never leave an appliance working without thermal protection.

Sensor – Samsung-Liebherr-Miele

Sensor – Samsung-Liebherr-Miele

The sensor relays the temperature reading from the evaporator to the electronic defrost timer, the defrost timer then determines if a defrost period is required.

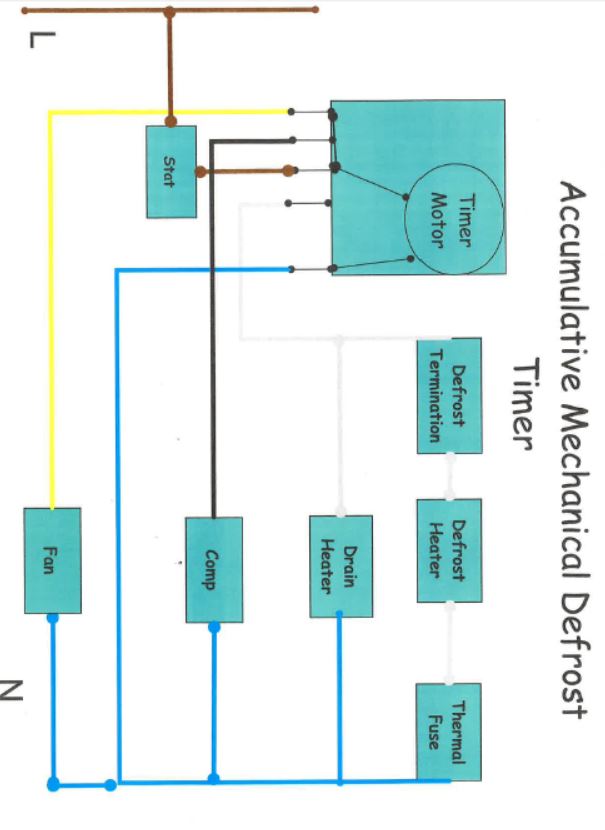

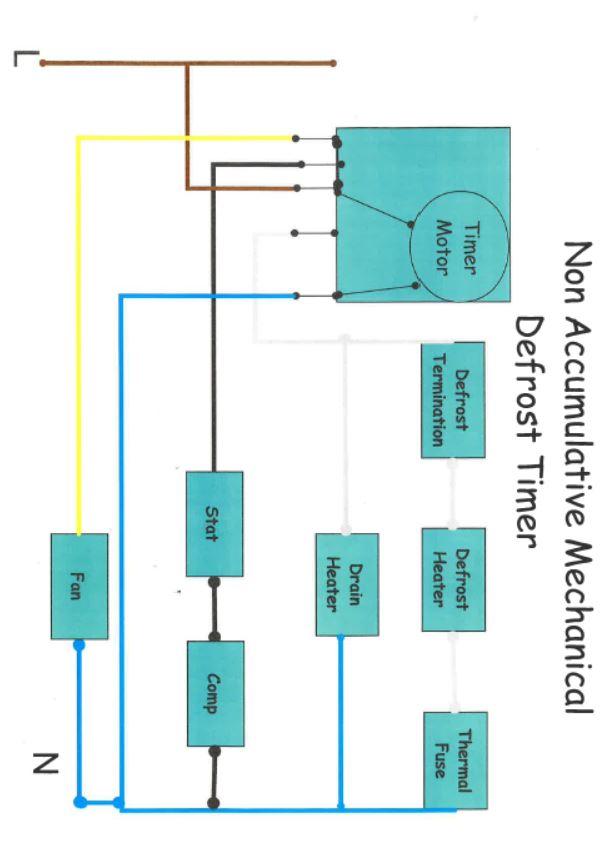

Defrost Timer (Mechanical) – Whirlpool-Maytag

The defrost timer switches betweenrefrigeration mode and defrost mode. A typical cycle is 8hrs refrigeration/30mins defrost time.

Defrost Timer (Electronic/PCB) – Bosch – LG

The electronic timer (PCB) is a more complex version of defrost timer it relies on sensors to initiate and terminate the defrost cycle rather than a set defrost pattern.

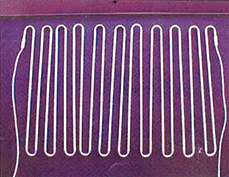

Defrost Heater – Samsung-Whirlpool-Maytag

The defrost heater can be wrapped around or installed within the coils of the evaporator. It melts any ice that has built up since the previous defrost period

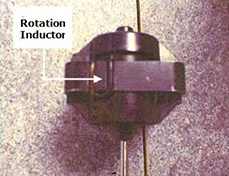

Fan Motor – Samsung-LG

The fan motor circulates the air inside the cabinet to help maintain an even temperature. All fan motor windings are fitted with a fuse which protects the windings against overheating and over current.

When replacing a fan motor you must ensure that the fan blade rotates in the same direction as the original fan motor. This can be checked by noting the position of the “Rotation Inductor” on the top of the fan motor and ensuring that the “Rotation Inductor” on the replacement fan motor is on the same

Sensor Resistance Values

All the sensors that are fitted to frost free appliances are NTC (Negative Temperature Coefficient), That means the resistance increases as the sensor temperature decreases.

| Temperature (°C) | __..

Approx Resistance (Ohms) |

|

| -30 | 47,000 | |

| -20 | 26,000 | |

| -10 | 15,000 | |

| . | 0 | 9,000

I |

| 10 | 5,500 | |

| 20 | 3,500 |

This chart can be used for both types of sensor, defrost period or refrigeration cycle.

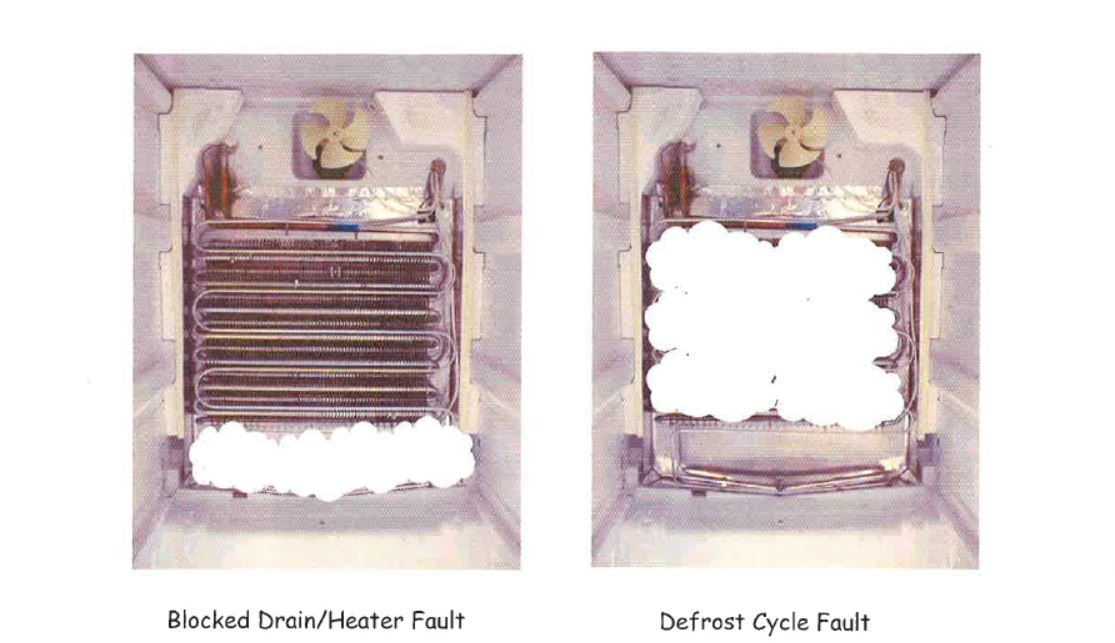

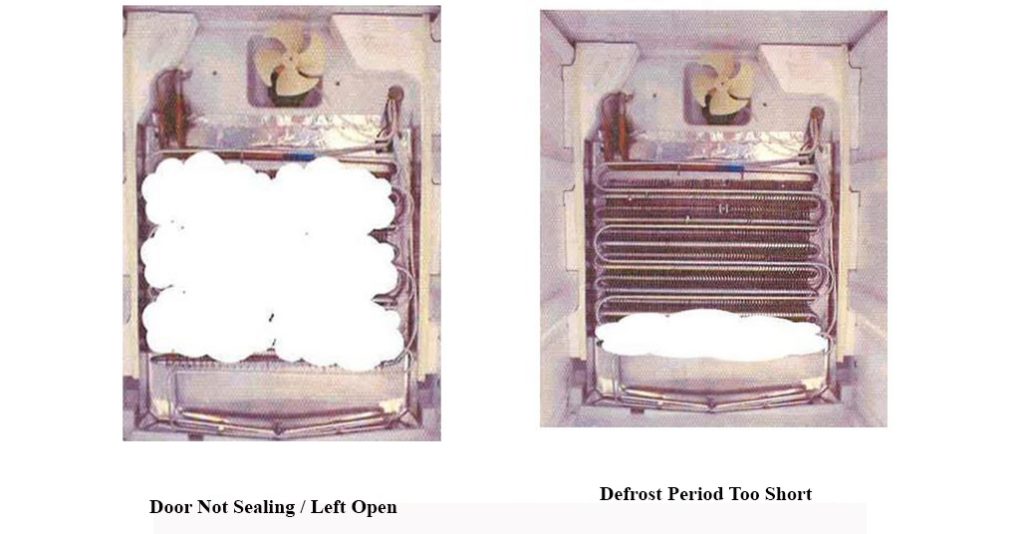

Typical Ice Formation

Typical Location Of Components